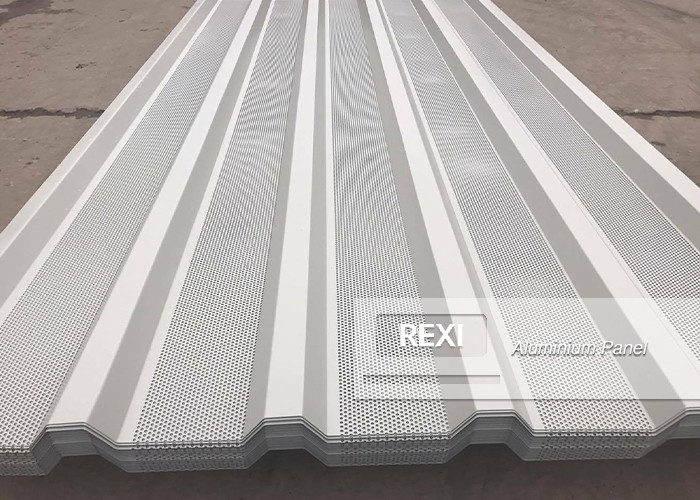

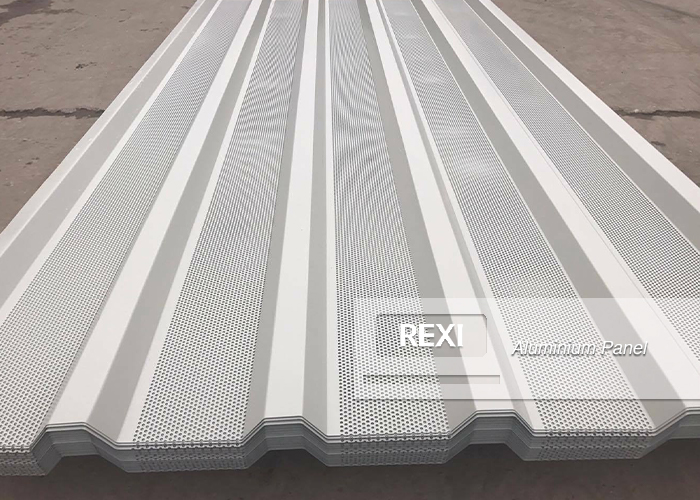

Aluminium perforated panel

Due to the development of materials and architects' pursuit of architectural appearance, aluminum perforated panel, as a new building exterior material, has been widely used in architecture. Aluminium perforated panel is made of aluminum or aluminum alloy through pressure processing with a variety of porous panel material.

Product Details

Due to the development of materials and architects' pursuit of architectural appearance, aluminum perforated panel, as a new building exterior material, has been widely used in architecture. Aluminium perforated panel is made of aluminum or aluminum alloy through pressure processing with a variety of porous panel material.

For the aluminium perforated panel, the perforation rate is the core factor that affects the display effect of the aluminum perforated panel on the building surface. Different setting of perforation rate of aluminium perforated panel will produce different visual effects of indoor and outdoor, night and day in the application of building skin. When looking from the outside to the inside, the aluminium perforated panel skin mainly expresses the whole rest effect of the building, which can avoid outdoor observation of indoor activities and better maintain the privacy of the interior space. When looking from the indoor to the outdoor, the aluminium perforated panel skin forms a certain extent of shielding to the outdoor landscape, and different perforation rates have a great difference in the extent of influence on the outdoor scene. When the perforation rate is low, the aluminium perforated panel has obvious shielding effect on the outdoor scene. When the perforation rate is high, the human eye can still feel the outdoor landscape activities through the pores of the perforated panel.

Another influencing factor is the aperture size of the aluminum perforated panel. The control of the aperture, hole spacing and arrangement can affect the visual clarity of the surface of the aluminium perforated panel. Combined with the perforation rate, panel thickness and other factors, it can reduce solar radiation and reduce energy consumption.

In terms of panel thickness, 1mm-6mm aluminum perforated panel is often used as decoration material for building facade. In the surface treatment method, there are mainly two kinds of powder spraying and fluorocarbon-spraying. Different colors can be customized according to the needs of owners

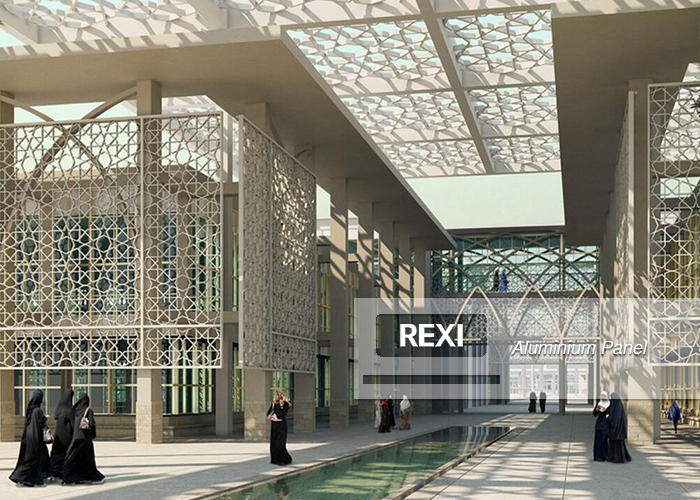

Aluminium perforated panel, as a derivative product of aluminum panel, naturally has the metal characteristics of aluminum, with good physical characteristics such as light weight, good ductility, low density and electrical conductivity. It is easy to produce a bright space effect in the application of building skin. Compared with the transparency of glass and the opacity of metal sheet, the perforated aluminum sheet achieves a translucent effect between the two, enriching the expressive force of the building facade. The technical characteristics and advantages of aluminum perforated panels in shaping the visual integrity of the skin and reducing building energy consumption make it possible to have great prospects in the application of building skin products.

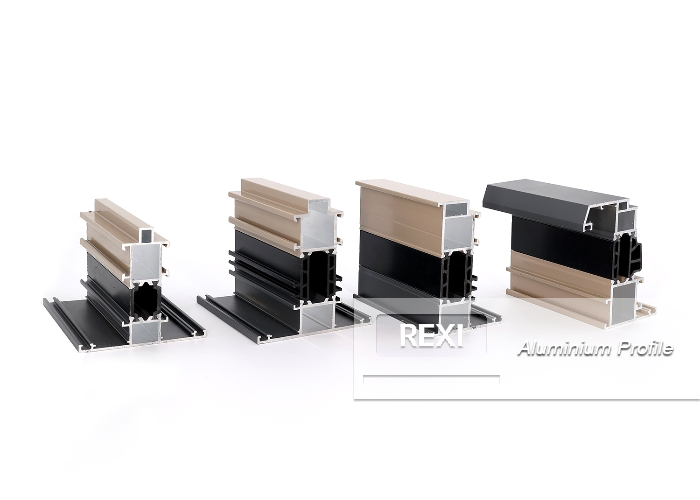

REXI Facade is China professional Aluminium panel manufacturer and has specialized in curtain wall for more than ten years which enjoys a good reputation. We also have a team who pursuits of excellence, not only the experienced sales can provide good sales service, but the technical personnel must provide the necessary technical support, which can ensure the rapid and effective to meet all customer needs. REXI aluminium panel cladding is your right choice, and we provide the modern design according to your requirements.

| Main Products: | Aluminium Cladding Panel |

| Aluminium Solid Panel | |

| Aluminium Perforated Panel | |

| Aluminium Carved Panel | |

| Aluminium Mesh | |

| Aluminium Mashrabiya | |

| Aluminium Ceiling | |

| Material Grade | Aluminum AA1100H24,1060H24, 3003H24, 5005H24 |

| Available Thickness | 0.5mm ~ 20mm |

| Surface Treatment | PVDF Painting / Powder Coating / Wood Grain / Stone Grain |

| Coating Brand | PPG / AkzoNobel / Jotun |

| Fabricating Process | Cutting, Bending, Jointing, Welding, Polishing, Surface Treatment. |

| Patterns Selection | Customized Design available, ODM Design. |

| Recommend Dimensions | 1200x 2400mm,1500x 3000mm, Customized size. |

| Certificates: | SGS,ISO 9001:2000,CE,KYNAR 500, etc |

| Production Capability: | 100,000sqm per Month |

| Delivery time: | around 20 days, depends on the panel drawings and quantity |

| Payment Term: | 30%TT in advance,70% Balance before loading, LC at sight |

| MOQ: | 1 sqm for thickness ≤ 3.0mm, 1000 sqm for thickness >3.0mm |

| More Service: | OEM, Small samples free |